Cold Boxes / Distribution Boxes

Custom vacuum insulated cold boxes equipped with internal complex arrangement of piping and process vessels operating at cryogenic temperatures.

CSA Corporate Sustaining Members:

Custom process equipment used in a variety of cryogenic and non-cryogenic applications throughout the liquid-gas supply chain for extraction, purification, liquefaction, distribution, storage and end use of gases and hydrocarbons.

Engineering, manufacturing, construction and maintenance services for cryogenic installations. Specialists in design and installation of cryogenic technologies for production, storage and handling of liquefied gases (LIN, LOX, LAr, LHe, LH2, LNG).

Developer and manufacturer of cryogenic equipment including design, production, testing and installation of helium and other custom equipment. Specializes in the development of new cryogenic technologies. Cryogenic engineering consulting available.

Designs, manufactures, tests and installs customer-specific vacuum insulated solutions for extremely low temperature applications (down to < 2 K), including for the transfer of liquid hydrogen from the liquefier/storage tank to the transport vessel.

Within Fives, the Cryogenics | Energy business line is specialized in the design, manufacture, installation and maintenance of brazed heat exchangers, cold boxes, cores-in-drums and cryogenic pumps from its Cryomec range.

Specialist in the design, engineering and fabrication of cryogenic equipment and piping systems for helium, hydrogen and nitrogen service.

Custom fabrication of ASME code pressure vessels, UHV vacuum chambers and cryogenic systems. Experience with cryostats, dewars, distribution boxes, heat exchangers, RF components, precision machining and welding.

Other Suppliers:

Design and analytic services for cryogenic heat exchangers, pre-launch LOX and H2 densifiers, MLI systems, H2 liquefiers, storage and transport dewars, mixed gas coolers and LNG systems.

Complex cryogenics systems which operate under low temperatures€”down to 1K. Equipment covers applications with liquefied helium, nitrogen, oxygen, LNG. Products include VIP (vacuum insulated piping), cryostats, valveboxes, transfer systems etc.

Manufacturer of cryogenic distribution equipment including semitrailers, microbulk rigid units and tank containers, with expertise in the safe and economic distribution of LIN, LOX, LAR, LNG, CO2, Liquid Ethylene and Nitrous Oxide.

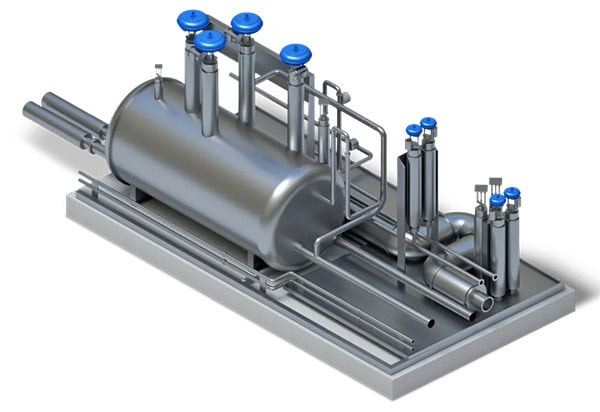

Loading Bay

Demaco

The Demaco loading bay is an essential solution for transporting liquid hydrogen safely and efficiently over long distances. It enables the easy transfer of cryogenic liquid from on-site storage to ships or trucks through vacuum insulated pipes. This system features valves, pressure relief mechanisms and cutting-edge monitoring and control technology. For enhanced safety and efficiency, all components can be integrated into a vacuum insulated box, optimizing cost effectiveness. This loading bay plays a pivotal role in facilitating the widespread use of liquid hydrogen, especially in areas distant from production sources. Constructed from stainless steel with vacuum insulation, Demaco offers both mobile and fixed installation options catering to various project sizes. They provide turnkey solutions tailored to specific loading bay requirements.

Product Showcase is an editorial feature in Cold Facts magazine. We invite suppliers to submit a release or contact us.

Attention Suppliers: If you need to update your supplier listing, please contact us.

Although CSA makes reasonable efforts to keep the information contained in these listings accurate, the information is not guaranteed and no responsibility is assumed for errors or omissions. CSA does not warrant the accuracy, completeness, timeliness or merchantability or fitness for a particular purpose of the information contained herein, nor does CSA in any way endorse the individuals and companies described herein or the products and services they may provide.